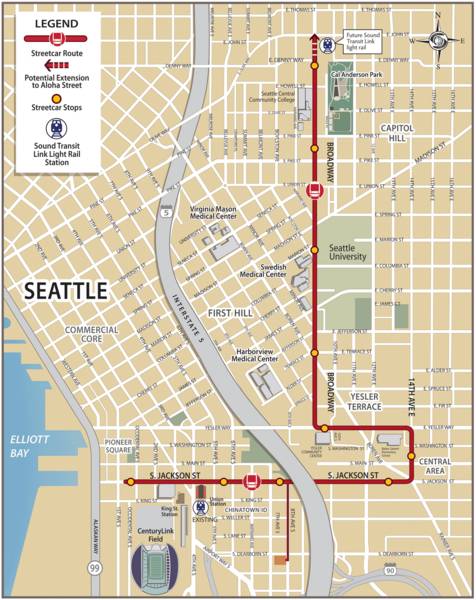

Here’s our look at the streetcar construction project details

Here’s our look at the streetcar construction project details

Friday, the first track was laid in place on Broadway as this work crew pounded out the first of some 700 welds that will be required to complete the 2.5-mile streetcar route connecting Broadway to Pioneer Square. It was not the first time Broadway has had streetcar tracks installed. But it is the first time the tracks will be connected with the painstaking thermite weld process that — slowly — creates a smoother, quieter seam and leaves a stronger, lower-maintenance connection.

The crew pounding the first connection out Friday afternoon was still getting its rhythm down. The foreman, apparently experienced, opted to step back as the mold was removed and embers flew — he’s ruined too many shirts that way, he said.

Here is more on the process from the Seattle Department of Transportation:

Recently, construction crews started excavation work for the inbound track on Broadway. This will prepare the roadway for the installation of track from Howell to Pine streets.

Below are some interesting photos to illustrate the work.

Rail Storage

The rail is delivered in 60-foot long segments called “sticks.” Each weighs about one ton! The type of rail being used on the First Hill Streetcar project is called “girder rail.” It has a low profile when embedded in concrete and is specially designed for urban areas. The girder rail was specified for this project because, compared to the more common “t-rail” system, it reduces hazards to pedestrians and to small wheeled vehicles such as wheel chairs, baby carriages and bicycles.Welding

The sticks are joined together using a technique called “flash butt welding.” Two rails are laid end to end with a small gap in between them. When an electric current is applied to the metal, the gap between the two pieces creates resistance and produces the heat required to melt the steel. When the rails reach the proper temperature, they are pressed together. Four sticks are welded together to produce a 240-foot long segment.Grinding

Here the welds are undergoing finish grinding. This produces a smooth ride.For more information and to sign up for email updates, visit the project website at: http://www.seattlestreetcar.org/firsthill.htm

This is so exciting. Thanks for the detailed update.

Thanks for the pics of the old streetcar ties. It really is an incredible feat to know that GM convinced our fair city to just pave over our streetcar network!

Interesting as Seattle will end up with three unconnected streetcar lines: this one, SLUT and the nonoperating 99 Waterfront. We all hope that the 99 will be resurrected once the viaduct has been removed. I’d like to see operate like the F line in SF. As far as the 99 is concerned, I wonder if the 99 could use the garage facilities for the Broadway/Pioneer line. The overhead can be constructed to handle both pantograph and trolleypole. SF has many miles of this kind of dual use overhead. This line should compliment the trolleybus system very well.